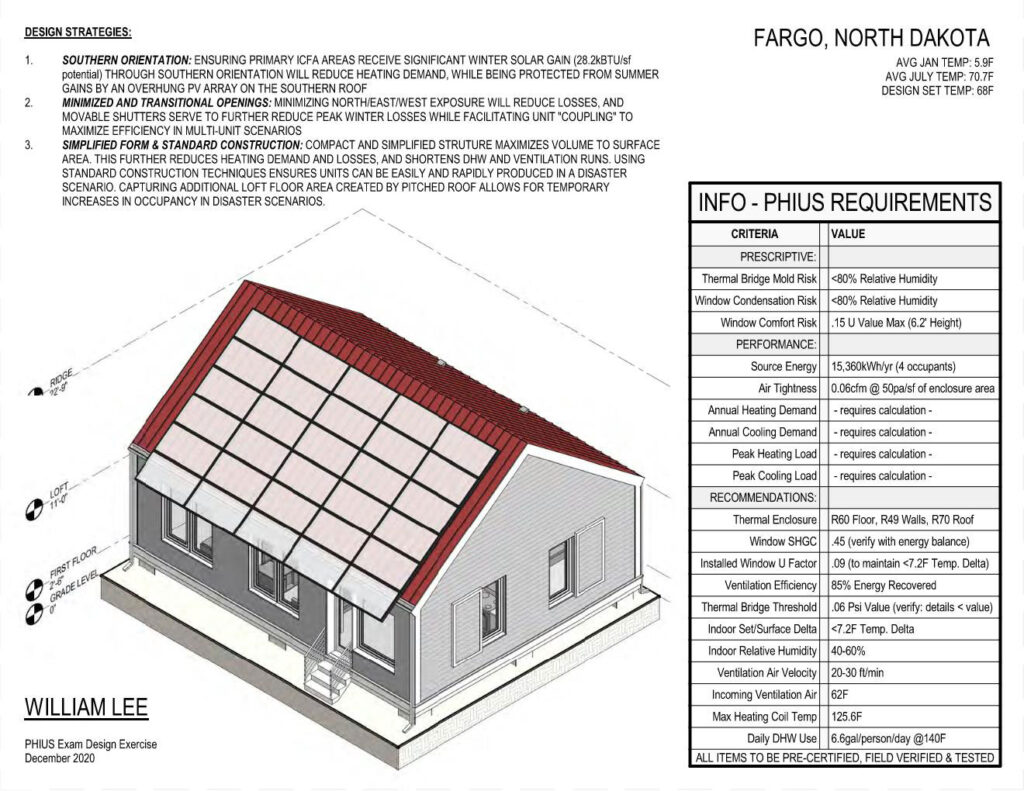

Mass Timber Topped Out

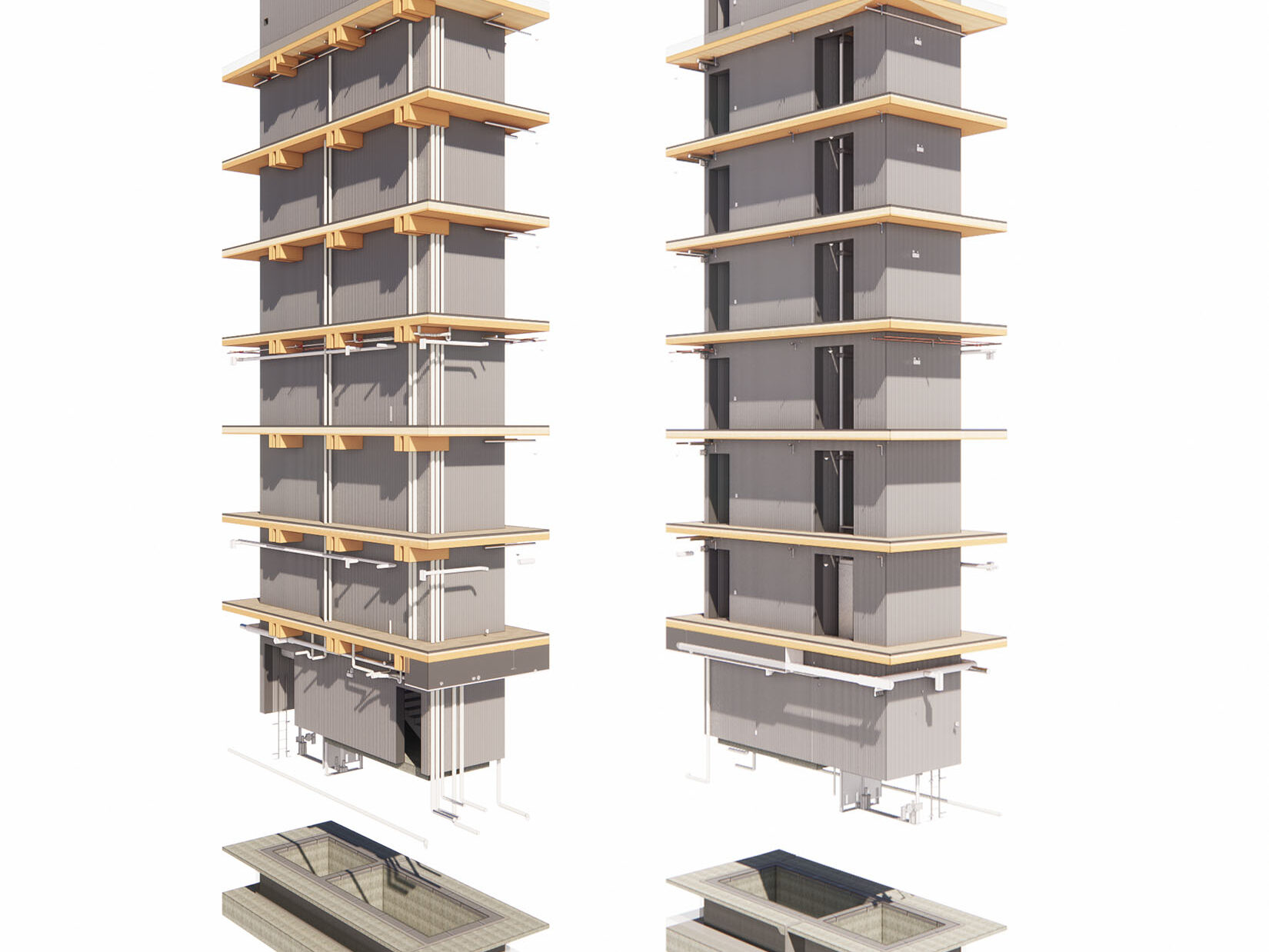

We conclude this year with the topping off of our 7 story mass timber project, 11 E Lenox. The installment of the last CLT slab went smoothly, becoming Boston’s first ground up mass timber project. We are overwhelmingly thankful for our incredible team and collaborators on this project. A huge shout out to our team who made this possible: Boston Real Estate Collaborative, D2 Development, Urbancore Development, Haycon, Nordic Structures, Code Red, H+O Structural Engineering, BLW Engineers, and Passive to Positive.

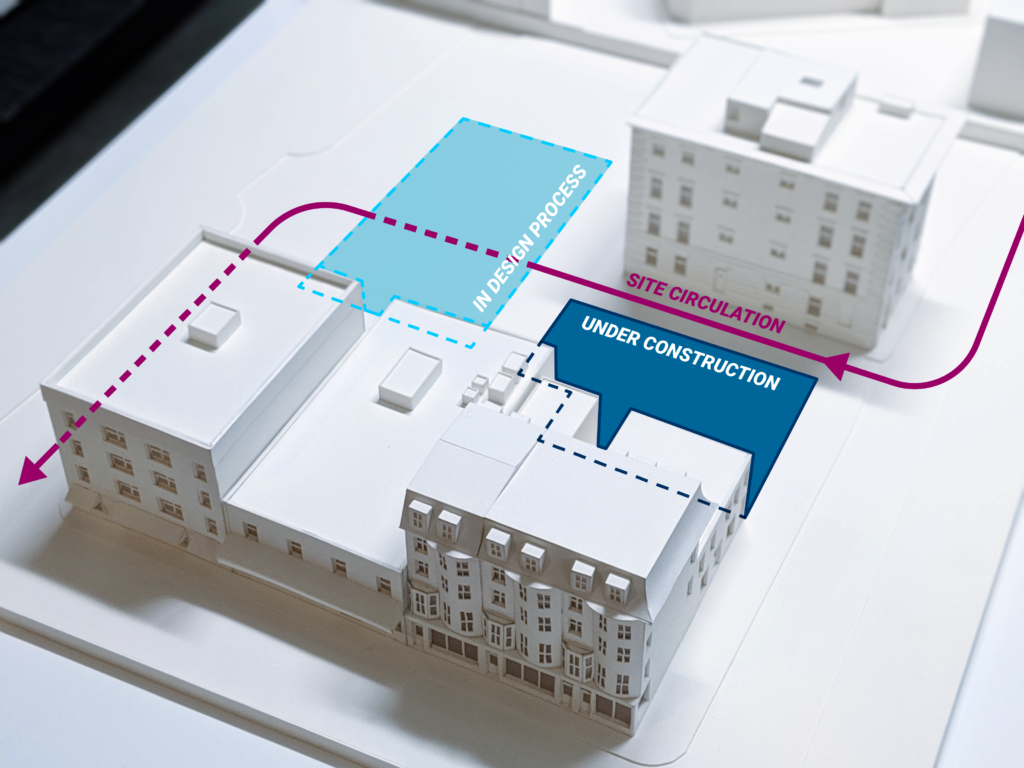

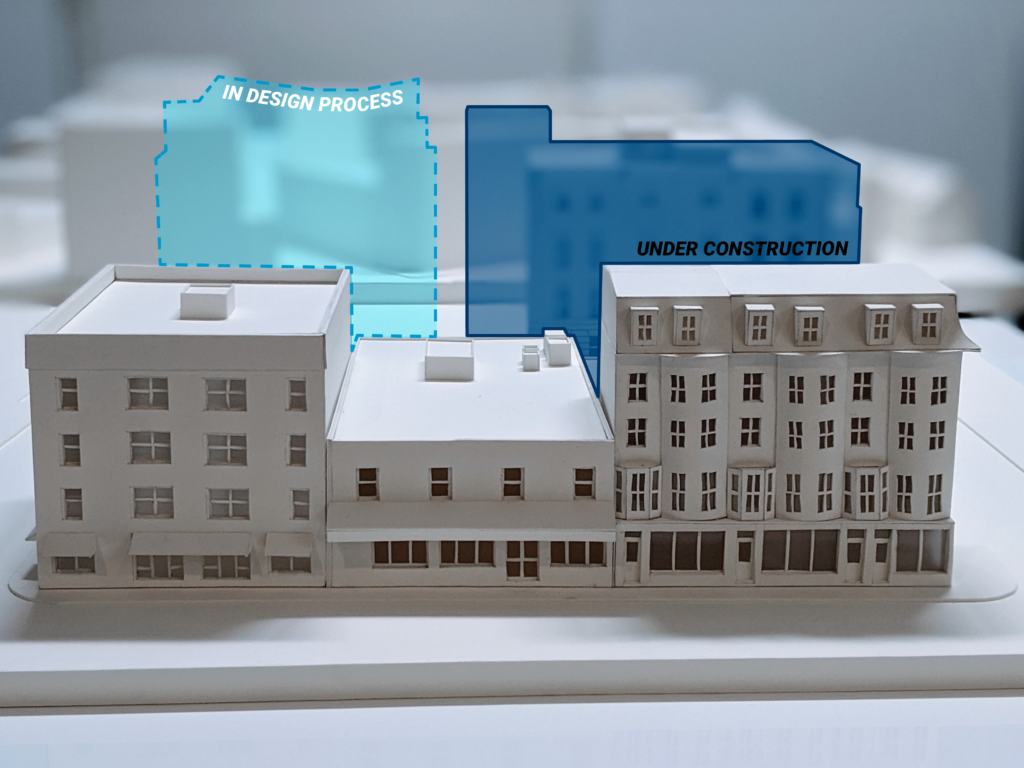

11 E Lenox Under Construction

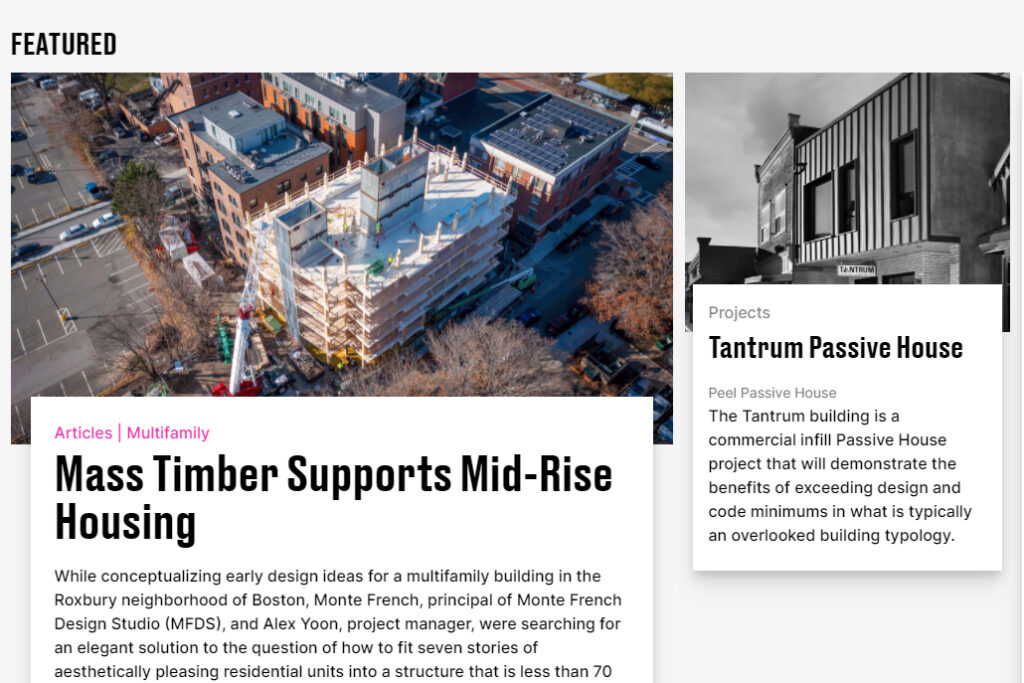

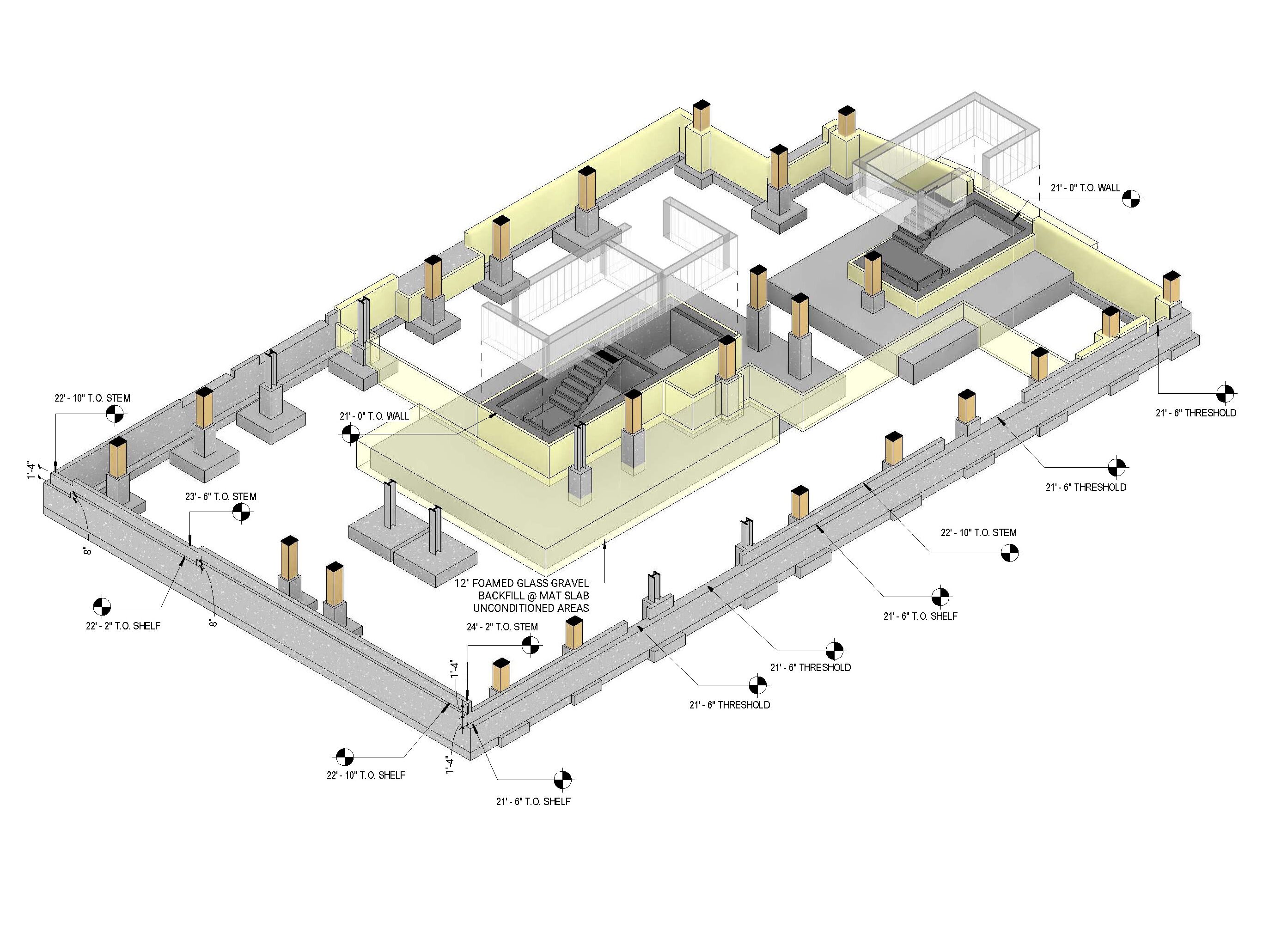

Boston’s first ground up new mass timber project is now under construction! When complete in Fall 2022, 11 E Lenox will be the first Passive House (PHIUS+ 2018) mass timber project in the Boston metro area. With foundations complete and the prefab modular steel form vertical cores now fully installed, the first mass timber components are due to arrive in less than two weeks. Stay tuned for more progress shots as the mass timber is erected!

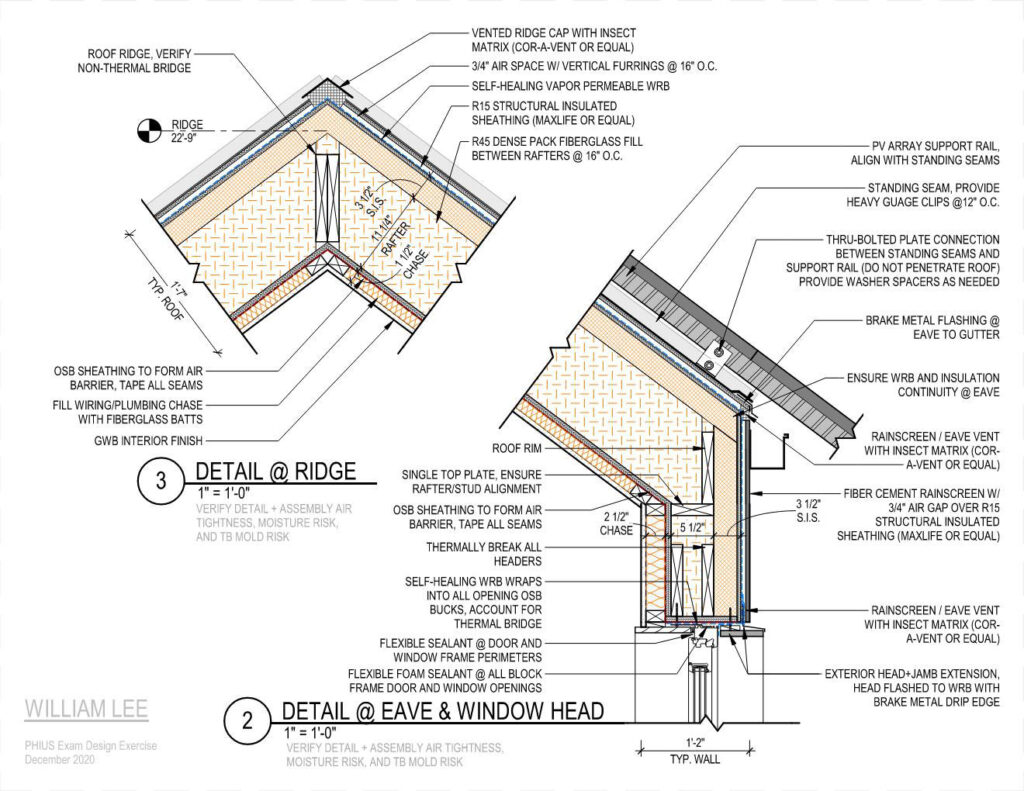

Roundtable Discussion on Mass Timber Collaboration

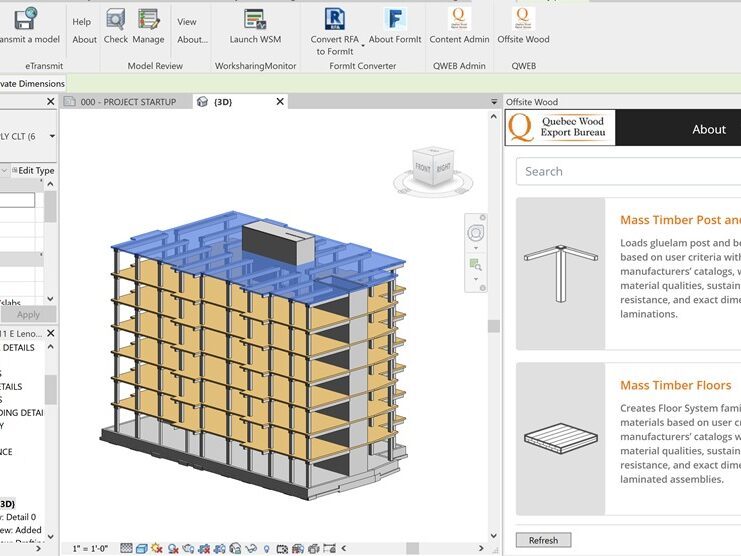

It was a pleasure to do a roundtable discussion on BIM, mass timber, and collaboration with Eli Gould from the Quebec Wood Export Bureau and Jean-Marc Dubois from Nordic Structures. Check out the ArchDaily post below, which features an upcoming Revit plugin by QWEB for mass timber design and our roundtable video. We discuss our 11 E Lenox project and how a pro-active and open-minded approach from the OAC team was key in developing this mass timber project from its nascence.

We wholeheartedly believe in utilizing the expertise of our team members, as well as from outside parties such as Eli and Jean-Marc – QWEB and Nordic have been great resources and wellsprings of knowledge and guidance.

Much thanks to our team for our past and current collaborations – BREC, Haycon, and H+O.

Link to ArchDaily post.

Adaptive Reuse Mill Buildings

Adaptive Reuse Mill Buildings

For this adaptive reuse project, a site study of these early 20th century power plant buildings revealed extensive craftsmanship and thoughtful functionality. They once supported bustling textile mills that operated 24 hours a day and employed thousands of workers. We are now working to bring new life into these buildings while maintaining their character and history.

CLT & Mass Timber Passive House Multifamily

A CLT & Mass Timber Passive House Multifamily Development.

We’re excited to announce that we are in development of a 7-story CLT and mass timber multifamily in Boston! In collaboration with Boston RealBosto Estate Collaborative, D2 Development, Haycon, H+O Structural Engineering, Code Red Consultants, and Passive to Positive – the project at 11 E Lenox will utilize a rapidly emerging sustainable structural system and integrate efficient energy and enclosure systems in pursuit of Passive House Certification.

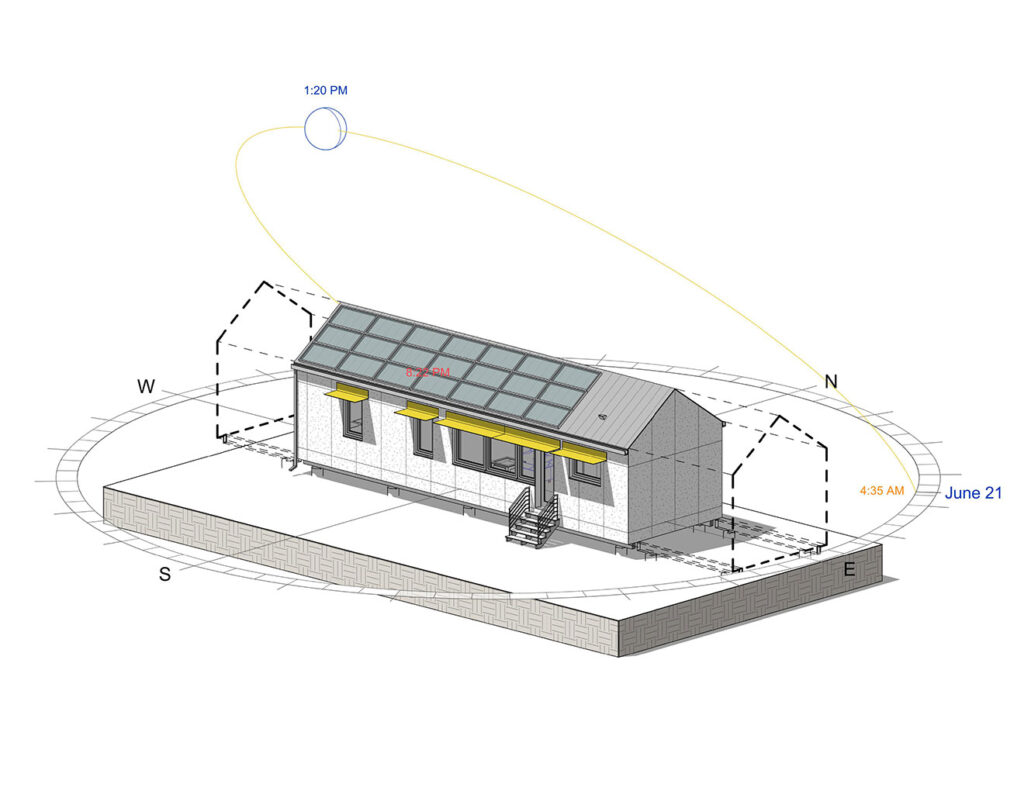

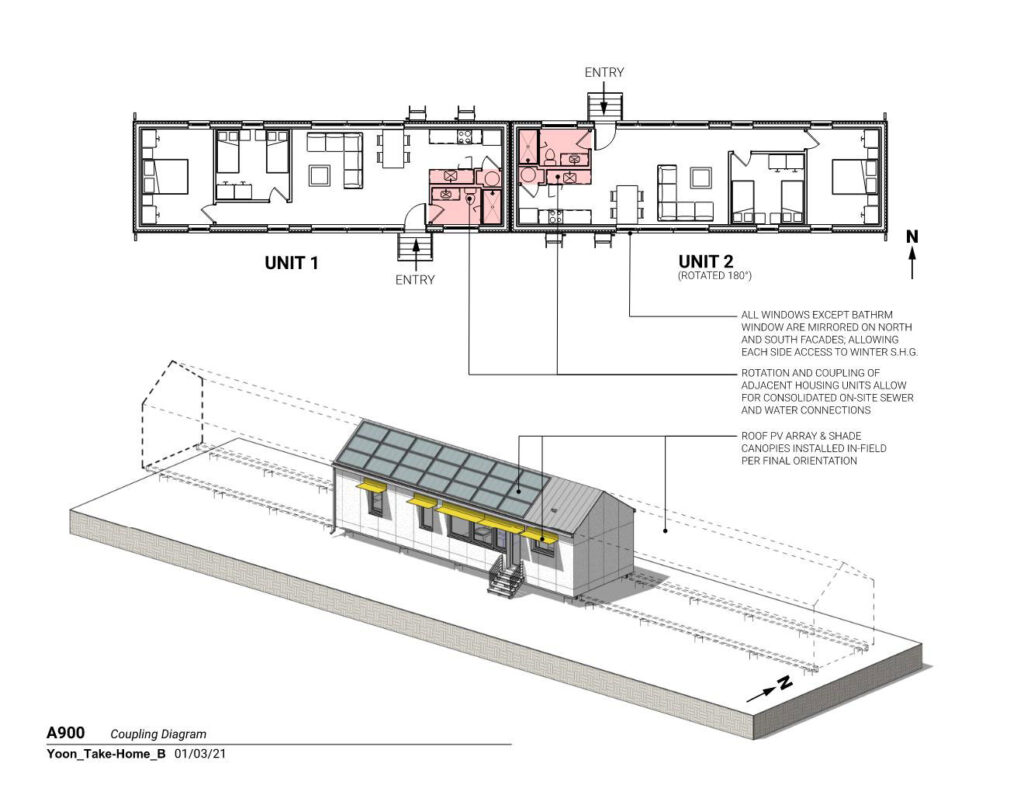

Some key facts and benefits of the design and various building systems:

– A carbon sequestering structural system composed of 5-ply CLT panel floors & glulam columns and beams

– Generous 8′-8″ ceiling heights while staying below high-rise classification with 7 floors under 70ft

– Prefabrication of floors, structure, and stairs project for a 2 month schedule savings

– No structural steel, no fireproofing, no podium

– Energy efficient enclosure assemblies and HVAC systems

The project will be a future case study as a market-rate low-carbon Passive House multifamily development in urban areas. The project is currently undergoing zoning, state building code, and BPDA approvals – stay tuned for more updates!

Project page:

https://www.mfds-bos.com/project/11-e-lenox/

Custom Rainscreen Cladding System R&D

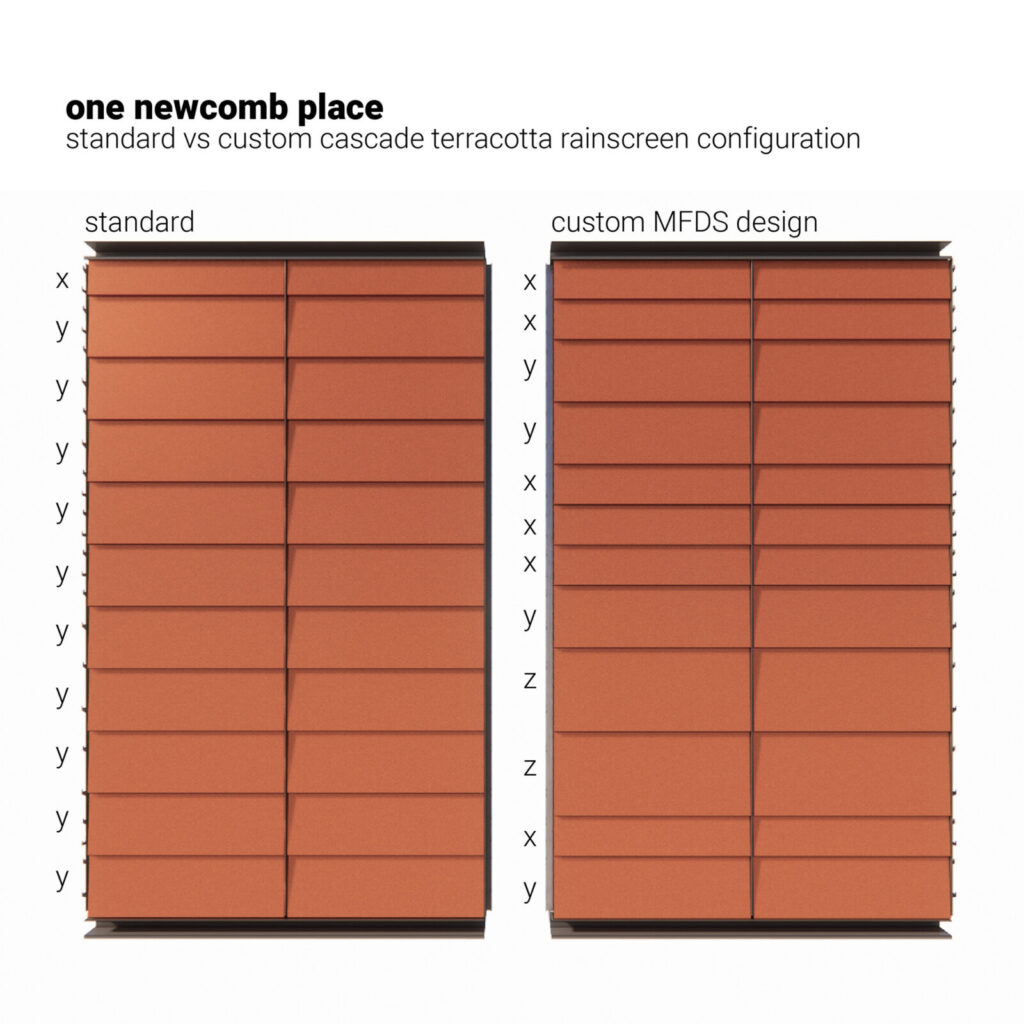

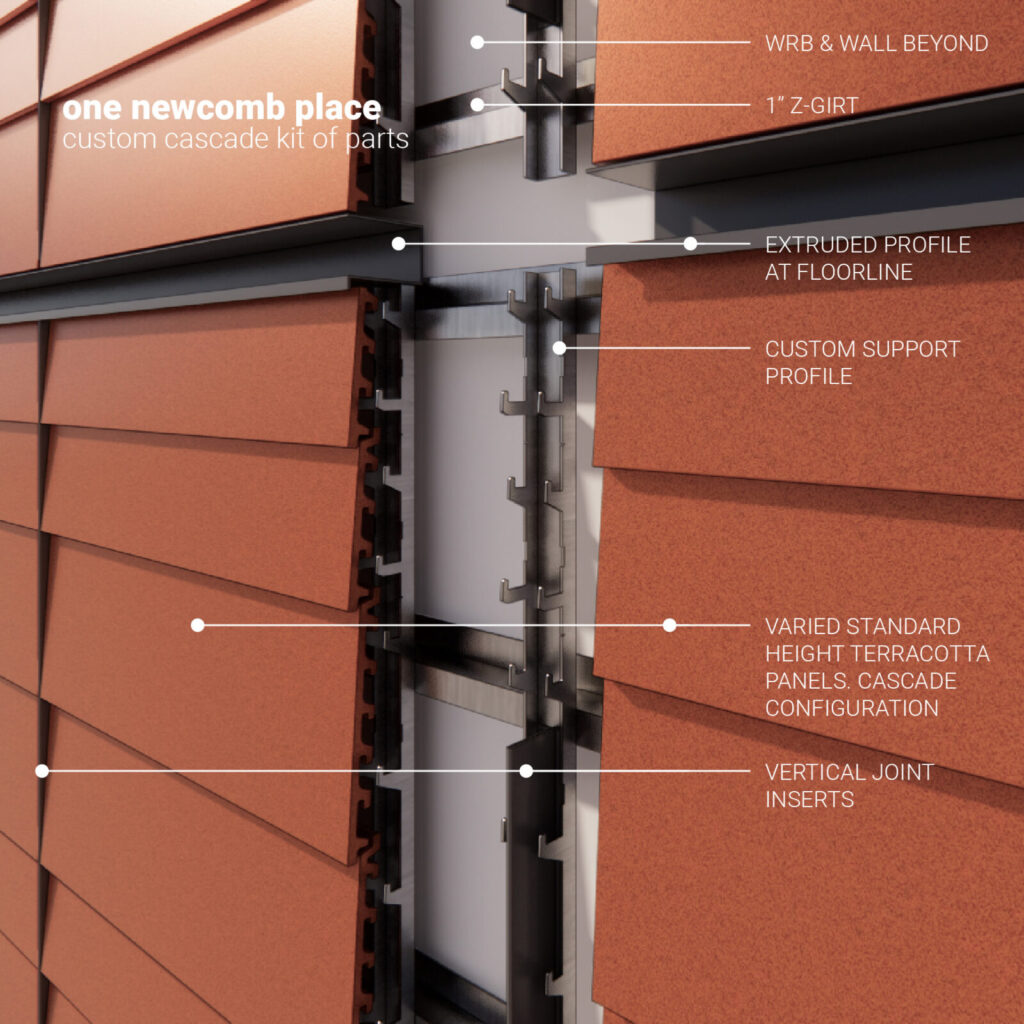

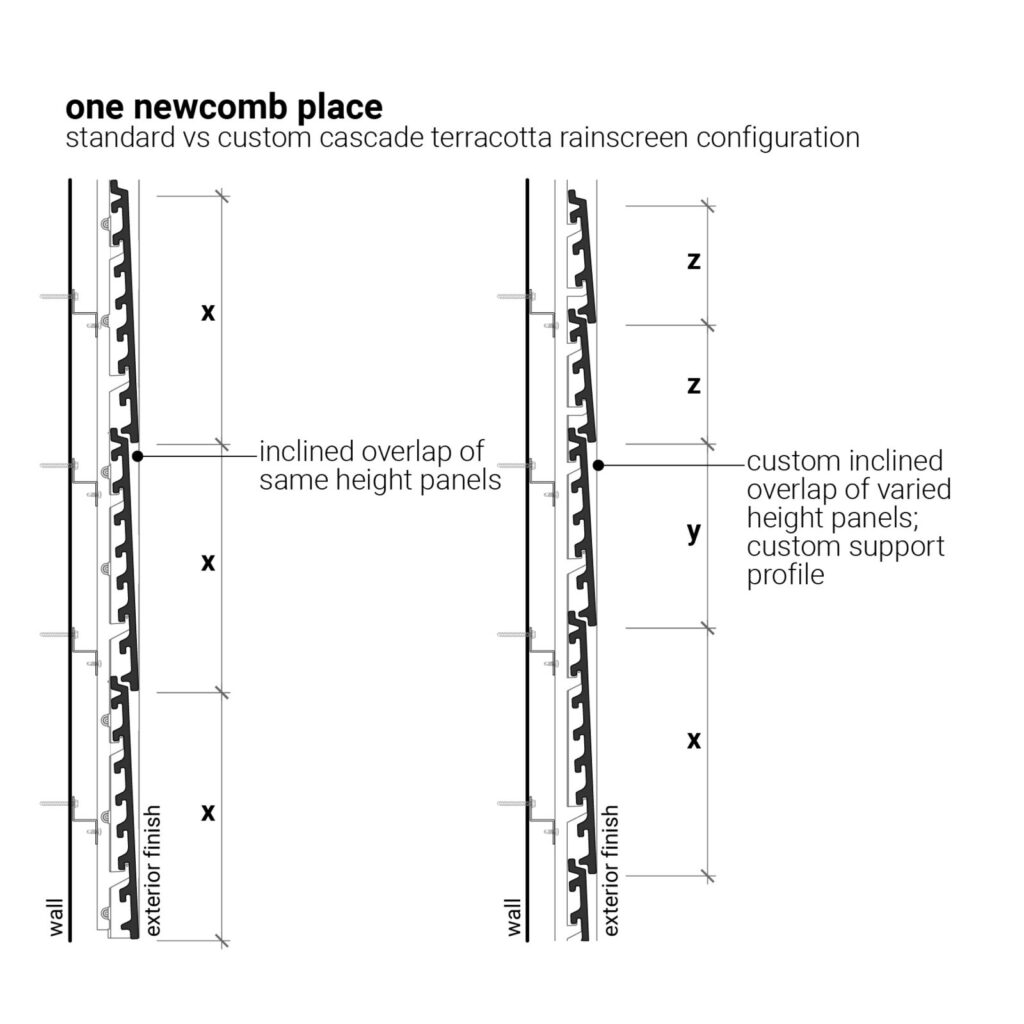

A custom rainscreen system designed by MFDS.

MFDS has been busy with R&D on unique façade cladding system designs. For One Newcomb Place, currently in construction, we designed a custom application of NeaCera Terra-cotta Rainscreens working closely with Avenere Cladding, the manufacturer. After touring their factory in Germany and meeting with their team, we took the base NeaCera Cascade configuration that used single height stacks and reformatted the vertical support profile to accept different height panels to create a unique variated product. The terra cotta is currently onsite and waiting to be installed, see the images below to see our process of research, design, and development of a custom system configuration.

The project was originally conceived as a fiber cement clad design as a cost effective solution, but MFDS researched various terra cotta manufacturers and systems to find Avenere Cladding, who offered a promising product and system that was cost competitive and far more visually appealing and robust.

When visiting the factory, we saw the potential of the cascade system configuration and its streamlined kit-of-parts. The team at Avenere were willing partners in exploring a custom support profile pattern – and given the variability of the system and the ease in which Avenere was able to implement it, the system may be offered as a product going forward as a configuration option.

Avenere’s excellent quality control meant very tight finish tolerances that provide crisp lines in the finished façade – which was critical in our new design that utilized varied panel heights that would have slightly different clearances and overlap from panel to panel.

Our custom design allows different height panels to stack and overlap to create a seamless pattern that repeats at every floor using standard panels height and without cutting any down to fit. The standard system using uniform heights would have had to have custom cuts or would not have registered with floor lines.

The base system offered is comprised of three pieces: the panel, the support profile, and the joint insert. We customized the support profile to accept varying panel heights, relying on the manufacturer’s tight finish tolerances to make the overlap tolerances work given the different panel heights have slight changes in overlap angles and clearances.

A simple change in modifying the support profile allows the system to still be cost effective while providing a substantial aesthetic impact with the varied panel heights. Designing the panel variation to repeat at every floor also allowed the support profiles to be manufactured in a single piece, furthering the ease of installation in an already minimal single wall support system.

50 & 100 Boatswain’s Construction Complete

50 & 100 Boatswain’s Way Construction Complete!

The interior renovations at 50 & 100 Boatswain’s Way in Chelsea, MA are complete! These lobbies are a shining example of how a few thoughtful design statements can completely transform a space, even when working within a tight budget.

For this project we used ceiling details, flooring patterns, and new furniture layouts to create a sense of scale and definition. Paired with fresh paint and updated light fixtures, these spaces are not only brighter and more inviting, but offer more functionality for the residents as well.

50 Boatswain’s Way

100 Boatswain’s Way

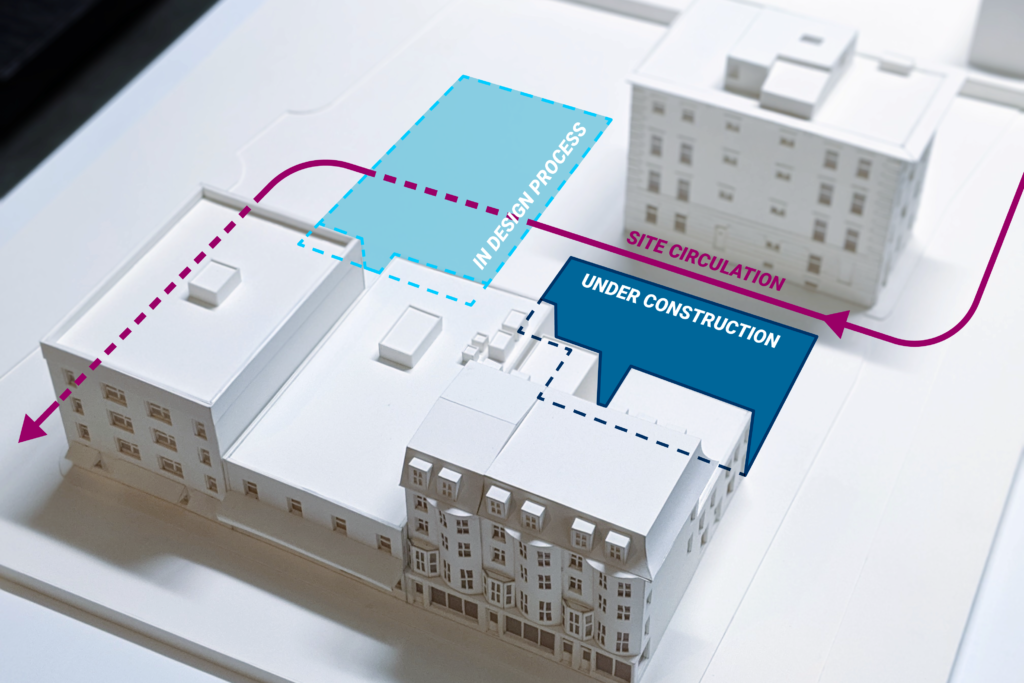

A Mass Timber & CLT Development

New project sneak peek!

We’re designing a CLT mass timber building! Too early to announce anything yet, but stay tuned as we explore and develop a novel and sustainable building typology.